Why the British steel industry is on the brink of extinction - or a green resurrection

Inside the blast furnace

We are standing at the base of Number Five blast furnace at the steelworks in Port Talbot. Outside, it's another gusty spring day in South Wales.

Inside the cast house floor, the air is thick with the acrid smell of sulphur and soot. Only a few metres away behind the refractory lining of the oven, is a bubbling reservoir of, for want of a better word, lava.

As we watch, an enormous drill on a robotic arm swings across towards the base of the blast furnace and the "tap wall" near its bottom. Even before the point of the drill makes contact, the side of the blast furnace is burning hot.

Flames of gas escape from cracks in the side, like an enormous kitchen hob. Then the drill penetrates the wall and there is a roar as it bores through the clay.

Suddenly, the side of the furnace is wreathed in black smoke and then it begins - a firework display of yellow sparks shooting out as the iron begins to escape.

We are all wearing flame-retardant protective clothing and it is just as well because for a moment the fireworks threaten to engulf us.

Then the smoke clears and suddenly we see it: a stream of yellow-hot liquid metal, lava, pouring along a channel in the floor beneath us. The room is bathed in a red glow and the temperature is rising.

Blast furnaces are extraordinary things. Is there any other contraption that better exemplifies humankind's determination to harness the elements and transform the world?

These massive cauldrons ingest hard rock, melt it down and transform it into the most important of all metals.

Iron and steel (the latter is simply an iron alloy with a tiny amount of carbon) are the backbones of the modern world.

They provide the skeletons of buildings, the shells of cars, and the fibre of bridges.

Pretty much every manufactured product you touch on a daily basis will owe its existence to steel: even if it doesn't have any inside it, it will have been made with machines and tools themselves made of steel.

And most of Britain's steel - more than three-quarters by weight - is made in blast furnaces like this.

In the top goes iron ore - today it's solid chunks from Brazil and processed pellets from Sweden.

There is limestone, which acts as a flux to sop up impurities in the ore, and something called sinter, a roasted mixture of iron ore dust and a few other things.

And then there's coal.

Steel coking at Tata Steel, Port Talbot

Steel coking at Tata Steel, Port Talbot

The coal - or rather coke, a form of heated, near-pure carbon - being emptied into the top of the blast furnace today is a mixture of the stuff they roast in the ovens on site here in Wales, as well as varieties from elsewhere around the world.

In it all goes, layer upon layer, night and day. The mixture bubbles and melts, then the liquid is tapped for an hour or so, then the clay in the tap wall is remade and the cycle begins again.

It is tempting to think of a blast furnace as an oven for melting metal, and given the temperature inside gets up above 2,000C (3,632F) - the hottest point was actually 2,237C (4,058F) on the day we visited, which is nearly twice the temperature of lava when it emerges from a volcano - that's understandable.

But it's actually slightly more helpful to think of it as something else: a chemistry vessel.

These furnaces are designed to chemically disassemble the iron oxide in the iron ore, removing the oxygen and any other impurities, and freeing the near-pure metal so it can flow down from the bottom of the furnace.

Steel rolling at Tata Steel in Port Talbot

Steel rolling at Tata Steel in Port Talbot

And there are few other elements in the periodic table which do this job - attracting oxygen atoms and helping purify raw ingredients like iron ore, or for that matter other ores too - as well as carbon.

The coal being emptied into the top of the furnace - and the coal being fired in the side of the furnace in granulated form - is not just there to heat the furnace.

Even more importantly, it is facilitating the critical chemical reaction which turns 60% pure iron into the 95% or so pure iron glugging out of the side of the furnace.

The reason iron production accounts for such a large proportion of global greenhouse gas emissions (7%, according to the International Energy Agency) - is that we have discovered no better, more efficient way of turning iron ore into pure (or rather purer) iron than deploying carbon, in the form of coking coal.

At this point, we're probably supposed to start talking about the carbon dioxide being the "waste product" from the blast furnace, but in a sense, carbon is the main product here while steel is the by-product.

For every tonne of steel made here in Port Talbot, about two tonnes of carbon dioxide are pumped into the atmosphere.

The upshot is that Port Talbot Steelworks, with its two massive blast furnaces (the country's biggest), is the single biggest carbon emitter in the country.

One of the things that makes climate change such a challenge both to grasp and to address is how disparate its causes are.

Most of the world's carbon emissions are spread across thousands or even millions of sites - the planes taking off every second from airports around the world, the car exhausts and boiler flues on streets around every country - but steel is different.

The thousand or so blast furnaces around the world produce comfortably the most concentrated source of mass carbon emissions.

All of which is why it is of no small significance that Tata Steel UK, which owns and operates the mill here, wants to shut down these blast furnaces for good.

Except there's a twist in the tale, because the prospective demolition of the blast furnaces is not a story of the steelworks closing, but, potentially, its best hope for survival.

Rolled steel coils at Port Talbot

Rolled steel coils at Port Talbot

A 'dying' industry

This is hardly the first time people have talked about shutting down the blast furnaces. There have been periodic crises in the steel industry for as long as anyone here can remember.

First, there was the demise of the British iron ore and then coal mining industries in the mid and late 20th century respectively.

Then came the rise of cut-price competition from Eastern Europe and then from China in the 1990s up until today.

While other countries around the world helped support their steelworks by subsidising energy and other costs or via trade protection, the UK allowed its steel industry to contract at a rapid rate.

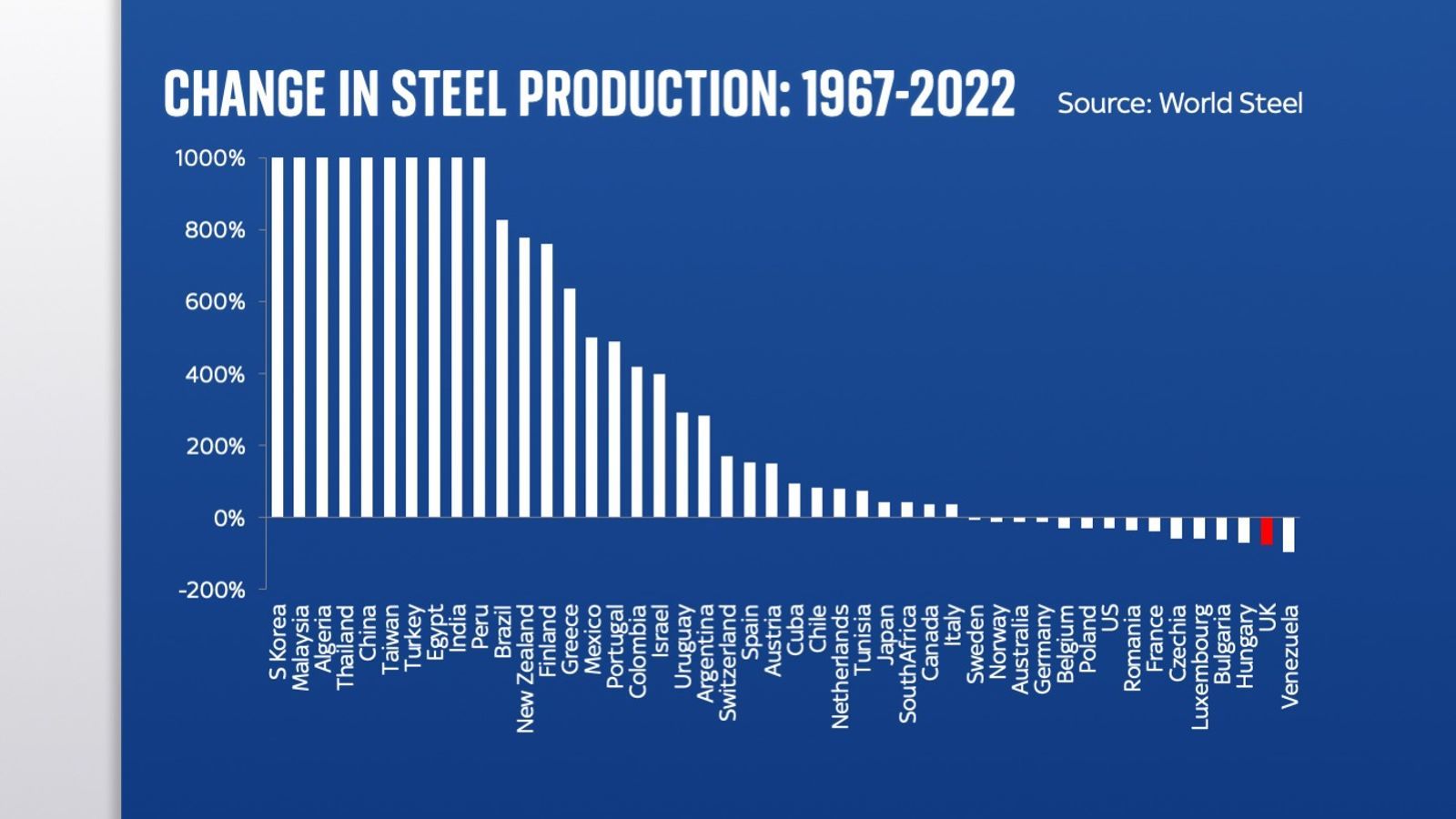

No other country in the world, save for Venezuela, has seen steel production fall as fast as the UK in the past half-century. The collapse of UK steel output is about far more than steel, though.

It's a symptom of a bigger story: this country has deindustrialised faster than every country save for post-Soviet republics, and the less stuff we make, the smaller our demand for steel.

Falling demand, rising costs: it's a potent cocktail.

As the steel sector has shrunk, most of those in Whitehall have shrugged their shoulders. Why should they support an inefficient, dying industry?

The happy by-product of deindustrialising at such a rapid pace was that the UK's carbon emissions would fall faster than nearly every other major economy.

The problem is that calling steel inefficient is to miss something important: steel is actually surprisingly productive.

Indeed, output per hour in steel has outperformed nearly every segment of the services sector which dominates our gross domestic product.

There's an argument that part of the reason the UK has had particularly weak productivity performance in recent years is that the structure of the economy has shifted so quickly towards services.

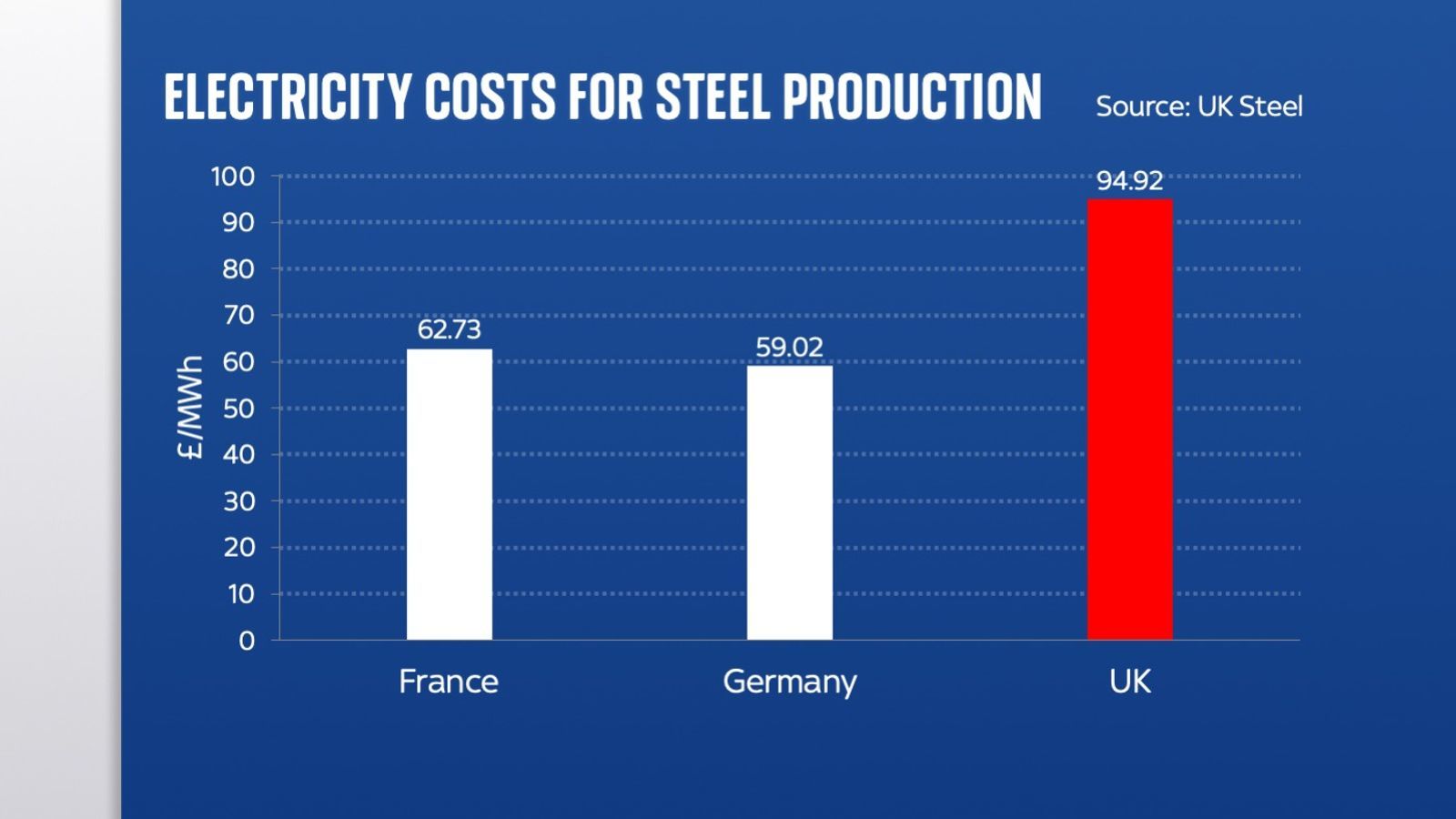

The steel industry suggests it needn't have been this way had they been on a level playing field. One of the biggest costs for steelmakers, alongside raw materials like the ones being tipped into the blast furnace at Port Talbot, is energy - which is astoundingly expensive for UK manufacturers.

When you add up wholesale energy prices, carbon taxes and network costs paid into the grid, UK energy costs are nearly double those in Germany and more than a third more than those in France.

Given many of these prices are controlled or set by the government, this brings us to an important point: the collapse of UK steel production is at least partly a consequence of government energy policy. And for as long as those energy costs are much higher than in other countries, there will always be a temptation to shift production overseas.

And that shift in production has had consequences. In the late 1970s, roughly a quarter of a million people worked in steel.

Today that number is down to only 39,000, with the biggest proportion here in Wales.

There used to be tens of thousands working here at Port Talbot alone; today there are roughly 4,000 workers, split between the blast furnaces, the coke ovens and the steelworks where iron is converted into steel (reducing the carbon content further) and then rolled and pressed into enormous coils.

Port Talbot

Port Talbot

Iron in their blood

Everyone has iron in their blood - oxidised iron is the element that gives it its red colour - but few have as much steel running through their family trees as these workers.

Their parents, grandparents and sometimes great-grandparents worked on the same site, sometimes doing much the same job. And these are good jobs - the ones in the steelworks tend to pay far better than those in other sectors.

"I told my son: it's given me a good living," says Alan Coombs, a third-generation steelworker at Port Talbot whose son now works in the cold mill on the site. "I remember my grandfather coming home from the coke ovens on his push bike. I remember the sense of pride when my father got made the furnace foreman."

But in recent decades, those working here have lived under a sword of Damocles. Many of those jobs have gone because of mechanical progress: steelmaking has become more automated and mechanised.

But many have gone because this country produces so much less steel. And year after year there have been rumours that Port Talbot too might soon face closure.

Other steelworks have met their demise, most notably the famous Redcar steelworks on Teesside, recently demolished to make way for a Freeport. Many have feared that much the same thing would happen to Port Talbot.

So what's different this time around?

Well, while the threat in the past was that the blast furnaces would be pulled down in order to end steelmaking here, the new plan being hatched by the site's Indian owners is to tear down the blast furnaces in order to save the steelworks.

That will sound a little strange until we take a detour a few hundred miles away to Rotherham, South Yorkshire.

A greener solution - fuelled by scrap

They have been working iron in Aldwarke, just outside Rotherham, for as long as anyone can remember.

The history of this particular steelworks goes back at least two centuries. This was where they made the cast iron that plated the hull of Isambard Kingdom Brunel's enormous steamer the SS Great Eastern.

There are some stained-glass windows depicting the ship and the old blast furnaces, but the Victorian headquarters building which used to house them has long since been pulled down and today they hang in the reception of a boxy set of prefab offices just inside the gates of the works.

Today the steelworks is a part of Liberty Steel, part of the empire of the controversial investor Sanjeev Gupta. To say there have been some ups and downs in its recent history is something of an understatement, but then again you could say much the same thing about most steelworks, since they all face similar pressures: most of all the need to compete with cheap Asian competition.

The blast furnaces have long gone because here they make steel in a different way to Port Talbot.

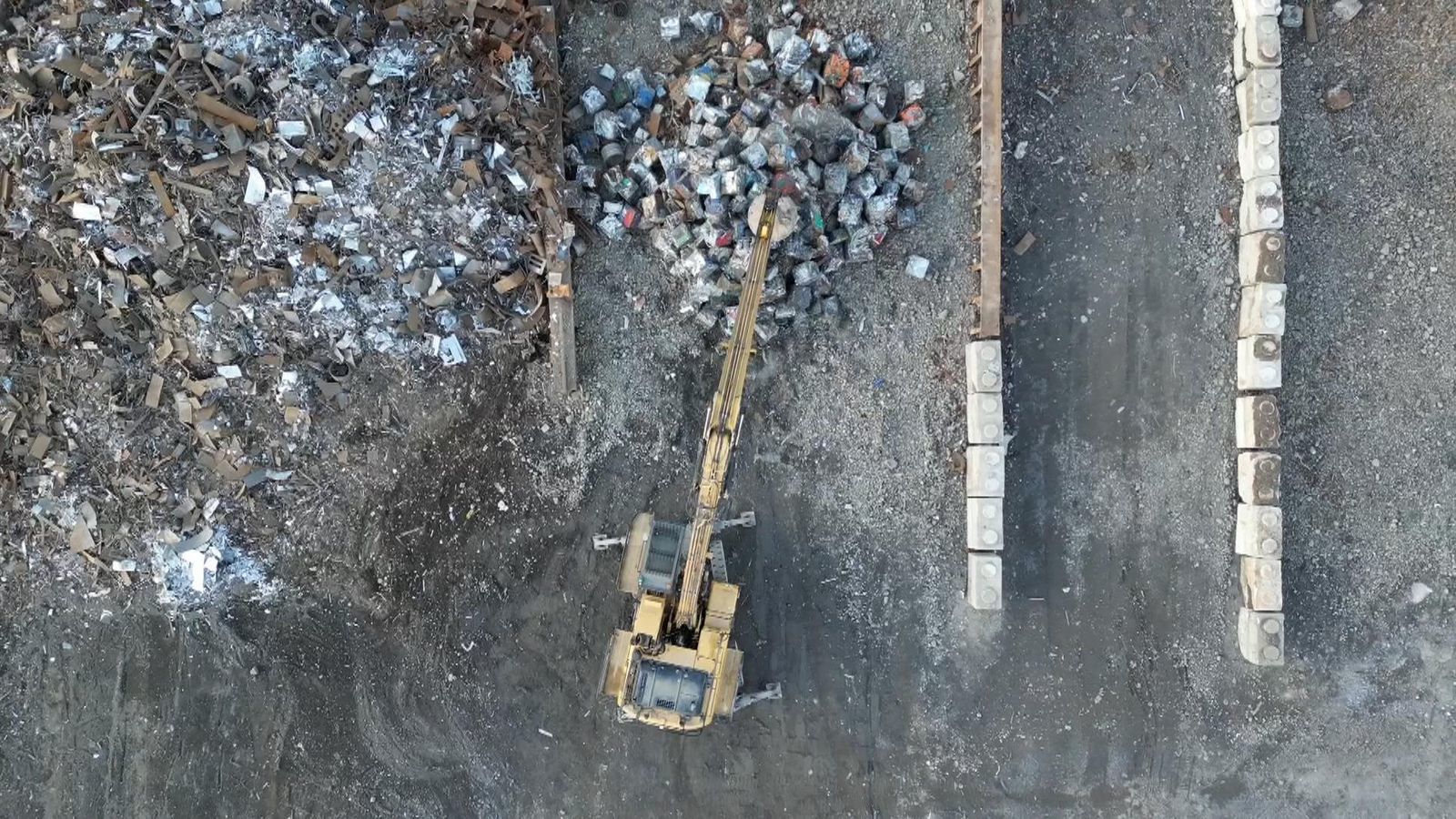

The clue is to be found not inside the vast plant itself but in the yard off to its side. Here you will find pile upon pile of scrap metal: clean, silver piles of old car parts; rusty old pipes and bars.

While Port Talbot's works are fed mostly with iron ore hewn from the ground, the steelworks here at Rotherham are fed mostly with scrap.

Electric arc furnace at Liberty Steel

Electric arc furnace at Liberty Steel

Long before the "circular economy" became the favoured buzzphrase of environmental economists, the steel industry has been turning old metal into fresh steel, to the extent that this is the world's most recycled industrial material.

The recycling happens in an enormous contraption known as an electric arc furnace.

The slightly dull name cannot do justice to the drama of what happens inside these furnaces. Three massive graphite electrodes are lowered into the cauldron and an enormous electric current of more than 50 megawatt-hours is run through them. There is an almighty sound of thunder, which is the appropriate word because these electrodes are quite literally creating a lightning storm inside the vessel.

Scott Jackson, a second-generation worker on the site who is now works manager, has vivid memories of the first time he saw the furnace in operation: "I just couldn't believe what I was seeing. The noise, the vibrations all through your body, the lightning show, the firework display - 5 November has never quite been the same."

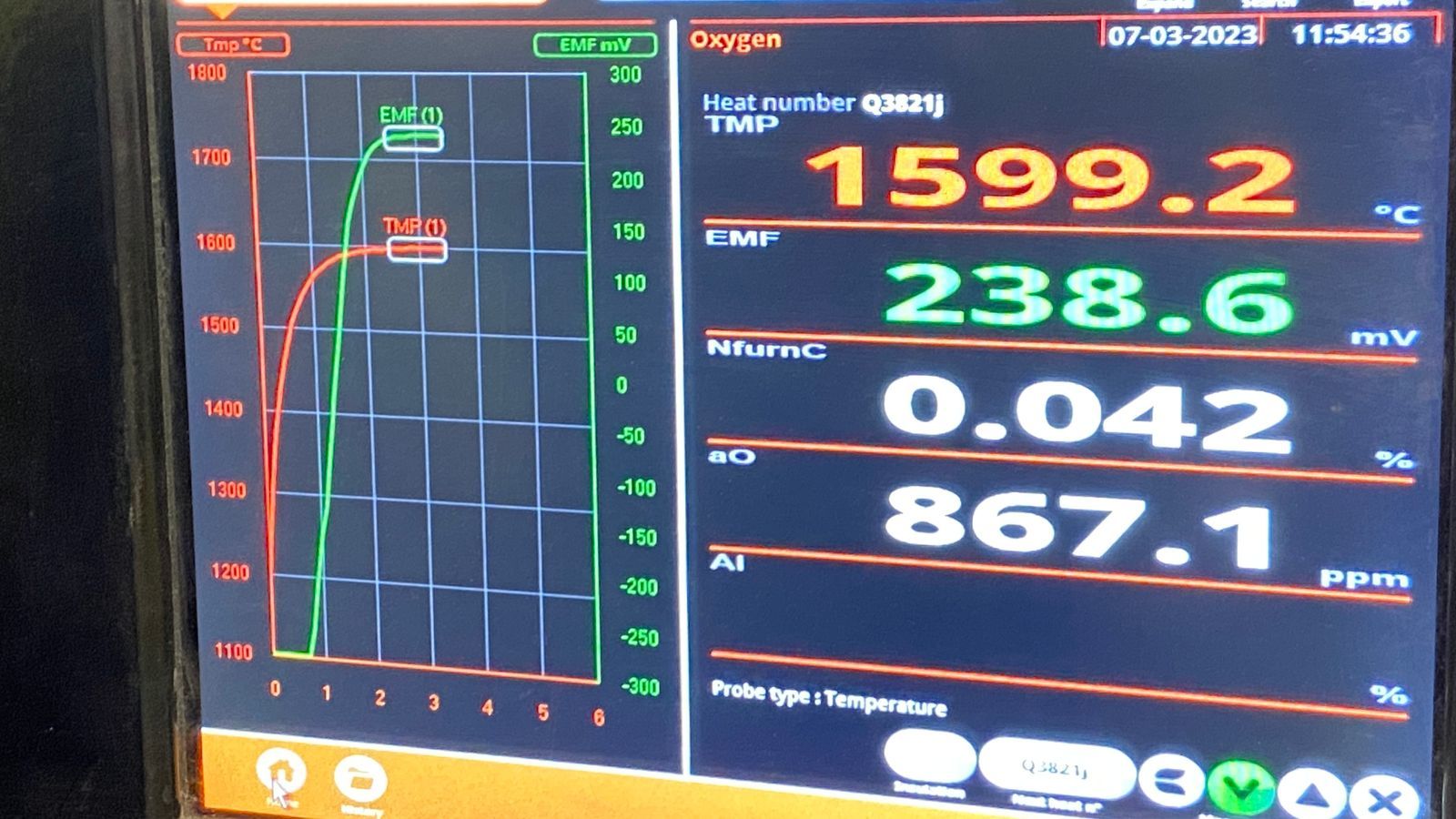

As the lightning and fireworks rage, the temperature climbs to 1,600C (2,912F) and the steel melts down into its molten, pure form.

Temperature control at Liberty Steel

Temperature control at Liberty Steel

As with the blast furnace, this is a bit of an oversimplification, because there is much more going on, a mysterious complex of chemical and thermodynamic reactions we're still yet to fully understand.

But when it comes to carbon emissions this is a far cleaner way of making steel than in a blast furnace. Liberty Steel likes to call it "GREENSTEEL", which is half true.

It's considerably greener than what we saw in Port Talbot, but there are still some carbon emissions: coal is thrown into the furnace alongside the scrap steel.

These days most electric arc furnaces have natural gas burners to help provide about a third of the necessary heat. This "oxyfuel" injection helps reduce the time needed to process the steel - down from four hours to about 40 minutes - and while there are plans afoot to replace the gas with green hydrogen, for the time being this process isn't truly green.

Even so, the electric arc furnaces here - the biggest in the country - are a hint of what we can expect in the future.

In the US, where these furnaces, mini-mills as they call them, have been a part of the industry for some time, they account for 68% of all steelmaking.

The UK, on the other hand, is a bit of an outlier, with far more reliance on blast furnaces than the US or for that matter the European average (only 22.2% of UK steel is made like this).

This is probably due to a couple of factors: first, it's likely a legacy of the fact that up until the 1980s much of the UK's industry was tied to its coal mining sector.

Second, Britain has long had some of the highest electricity prices in the developed world.

With coal so available and electricity so expensive, there was little incentive to shift from coal-centric blast furnaces towards power-centric arc furnaces.

Molten steel ladle at Liberty Steel

Molten steel ladle at Liberty Steel

It's all about energy

It's a reminder that with heavy industry, nearly everything comes back to energy prices.

Faced with the Ukraine war, when electricity prices shot up to unprecedented levels, the furnaces here in Rotherham were shuttered.

When they restarted, for a while they were only switched on at night, since prices between 11pm and 6am were comparatively lower than during the peak hours of the day.

And no wonder. When the furnaces here are switched on, they drain more power more quickly than any other appliance in the UK.

The site has a direct connection to the National Grid, with pylons plugged into a substation a few hundred metres south of the steelworks themselves.

The cost of electricity isn't the only reason not everyone makes their steel with electric arc furnaces these days. Up until recently, the conventional wisdom was that while recycled steel was perfectly good for low-grade uses like the reinforcement bars you put inside concrete structures, it was too impure for higher-end uses such as in car chassis.

It is fiendishly hard to remove some impurities from this steel - especially copper, which has a tendency to creep into scrap and hence into the furnace.

But this brings us to a paradox, for the steel milled here in Rotherham is among the highest quality in the country.

While much of the steel made in Port Talbot goes into construction, tins, automotive and other uses, this place focuses on high-grade steel for defence or aerospace use.

After watching the arc furnace do its thing, we walk through the Liberty Yard where large ingots are slowly cooling and come across one which is aerospace grade.

After being melted down another three times and milled into shape, this will become critical parts of planes.

They like to say here that every three seconds a plane lands with one of their steel grade - 300m as it's known - in the landing gear.

This is one of the best steels there is: light, strong and able to perform in extreme temperatures. It underlines that, contrary to conventional wisdom, there is little you can't do or make with recycled steel, all of which is why Tata's plan is to pull down its blast furnaces and replace them with a pair of electric arc furnaces.

When the wind blows

The day before we arrived in March, the Welsh Government announced the creation of a Freeport encompassing Port Talbot and Milford Haven in Pembrokeshire. It was widely seen as a breakthrough for what has become one of the more deprived parts of the country.

Based on the Freeport plans, there will be a hydrogen hub at Milford Haven (currently one of the country's most important liquefied natural gas terminals) and a fleet of floating wind turbines in the Celtic Sea.

The Tata Steelworks is a critical part of the plan. It will, according to the prospectus, be able to provide much of the steel in those wind turbines.

And if it manages to revamp its site, replacing those blast furnaces with electric arc furnaces, that steel will be among the greenest in Europe.

The UK, with all its cars and buildings, generates comfortably enough scrap steel to provide all the steel it currently uses.

At the moment we export most of that steel overseas to be recycled into metal and products we then import all over again. Why not cut out the middleman?

Squint a bit and there is an intoxicating, optimistic vision of how this part of the country might thrive.

Many of the jobs lost in the blast furnace will be replaced with new highly-paid jobs in green steel production.

The region will leverage its natural geography (the coastline, the deepwater ports, the wind off the coast) and its long expertise in engineering and manufacturing to become an industrial powerhouse again.

But there are some challenges.

The first, predictably, comes back to money.

Replacing the blast furnaces here with electric arc furnaces could cost up to £3bn, especially if Tata uses the opportunity to replace some of the aged steel production facilities here too.

So Tata is asking the government for cash. It started by demanding £1.5bn; the government replied with an offer of £300m.

Talks are ongoing. Something similar is happening on the other side of the country in Scunthorpe where British Steel, the Chinese-owned group, operates the UK's other two working blast furnaces.

"Governments in Europe are throwing billions into our competitors' industry - in Germany and France and Spain," says Henrik Adam, Tata's UK chairman. "We are only asking for a similar deal.

"We want to have fairness, a fair deal for our communities, for our people, and for the UK to be competitive in future."

But for many, especially free-market economists, it seems laughable that steel companies should be attempting to squeeze so much money out of the government.

It's easy to forget in the post-COVID era that a billion pounds is a lot of money - enough to fund the construction of countless schools or hospitals.

Why should taxpayers be subsidising private firms with a track record of losing money (and being repeatedly bailed out)?

Indeed, if Britain resisted the temptation to subsidise its industry then it could benefit from cheaper, imported steel which would in turn ensure British consumers pay lower costs.

The cost of modernisation

The steelmakers have two answers.

First, they are in a hurry to decarbonise not because it makes economic sense but because the government has legislated to get to net zero carbon emissions by 2050.

That legal imperative is not the only thing helping drive this change, but it's a lot of the explanation so, say the steel companies, surely the government should bear some of the financial burden?

Second, pretty much every other government is helping subsidise green steel plans like these. All the steelmakers want, they say, is a level playing field.

Look across Europe, and further afield, and you can see their point: the French, Italian, German, Canadian and Spanish governments are all throwing money at their steel industries.

The US Inflation Reduction Act provides hefty subsidies for green steel. None of this implies that state subsidy is the "right" thing to do, but it is one of those things which could mean businesses choose to invest not in the UK but elsewhere if the price is right.

But even if the steelmakers achieve their aims there are big question marks.

The first problem is that making steel in this greener way involves less manpower.

At the moment Port Talbot has a vast hangar containing a basic oxygen converter that turns the pig iron coming out of the furnace into pure steel, but since electric arc furnaces produce steel directly, there's no need for this entire operation.

And if Tata modernises other bits of its operations further job losses are likely. Indeed, Sky News understands that internal estimates imply the number of workers at Port Talbot could be reduced from 4,000 to as few as 1,000 workers.

The second issue is that, as we've seen in Rotherham, this method of steelmaking isn't entirely green.

You still need some iron ore pellets to go into the furnace to bolster the steel, you still need to burn natural gas and even some coal (though some of that can be replaced with zero-carbon fuel).

There will still be some carbon emissions, albeit less than before. For truly green steel the industry might need to adopt another system altogether, "direct reduced iron", with hydrogen used to remove the oxygen in iron ore.

None of Britain's big steelworks is considering a DRI plant, but a prototype operation in Sweden is already pushing ahead with one.

The policy puzzle

Back in Whitehall, it's not clear what the government's strategy is.

Since Theresa May legislated to get to net zero by 2050 we have had a succession of different Conservative administrations, each with a starkly different flavour of industrial strategy, culminating with a prime minister who seems far less interested in manufacturing than finance and a business secretary who told me in her first interview that it wasn't a given that Britain ought to have any steel industry at all.

And the deeper you dig into government policy, the more flummoxing it is.

Consider the following paradox: even as the country's biggest steelmaker says it is planning to tear down its blast furnaces, negating the long-term need for coking coal, the government has approved the building of the first new coal mine in decades, digging for coking coal in Cumbria.

That would make some sense if there were, for instance, a blueprint to convert the blast furnaces in Scunthorpe so the carbon emissions could be sequestered beneath the North Sea, but that doesn't seem to be the plan at present.

It's a bit of a muddle, and muddles are not the best thing when companies and governments are pondering the outlay of enormous sums of money.

In theory, there are promising markets for UK-made steel.

Consider one of the biggest ongoing infrastructure projects of the current era: the offshore fleet of wind turbines being deployed off Britain's coast.

The vast bulk of materials going into those turbines is steel of various sorts, primarily the steel in the enormous towers that jut out from the waves.

But it turns out that barely any of the steel in the turbines currently dotted around the country was made here.

Why? It comes back to the cost of energy and the difficulty of competing with low-cost imports.

When Liberty Steel pondered the construction of its own wind turbine at its Dalzell steelworks in Scotland it worked out that even though it was producing its own plate steel, the numbers simply didn't add up.

"It's not cost competitive," says Liberty's chief transformation officer, Jeff Kabel. "Between the energy and [the price of] imports, if we were going to develop our own wind farm it's cheaper to bring it in right now.

"I've looked at the cost structure of doing it as an independent investor in that project, as you do. And it's on the line and it shouldn't be on the line."

How the wind turbine market has functioned up until now is that the vast majority of steel in our turbines has been made in Asia and then shipped across the world.

This is part of the explanation for why the cost of wind turbines has fallen so sharply in recent years.

But it comes with a carbon cost. While the blast furnaces at Port Talbot produce two tonnes of carbon for every tonne of steel, those in Asia, and for that matter Ukraine and some other parts of the world, produce three or even four tonnes of carbon for each tonne of steel.

It's not implausible that if it rapidly built out green steel facilities, Britain could provide much of the steel for its wind turbine fleet. The problem is that steel will end up being far more expensive than the cheap stuff currently used to make these structures.

Our already-expensive electricity prices could get comparatively higher.

A tantalising prize for the UK and green energy

Even so, it underlines another important point.

It's tempting, when pondering the future of steel, to focus mostly on the primal processes that turn raw ingredients into iron or steel - indeed that's precisely what I've done in most of this article.

But just as much thought needs to go into the other processes elsewhere in steelworks. Are we pressing that steel into the right kinds of products?

There are more than a thousand different varieties and while the types made by UK steel mills have served very well in the past, when we were using them to make rails and car bodies and food tins, might there need to be a different mix of products in future?

We are pondering this as we make our final stop on the tour of the Port Talbot steelworks.

We have seen the iron ore being turned into pig iron and then blasted with pure oxygen to become low-carbon steel.

We watched as the molten steel was emptied into ladles and then into the casting moulds, which look a little like a set from the film Aliens, as that liquid metal turned into a solid slab.

We stood above the metal - still more than a thousand degrees hot - as it rolled slowly towards the oxygen flame cutting it into slabs and watched as each slab was lifted away towards the next step of its journey.

Then we enter the hot rolled strip mill, where they take those red-hot slabs of steel and send them careering down a line to be squeezed and rolled between enormous mechanical presses.

What begins as a thick 30-foot-long slab ends as a rolled coil of thin metal, sometimes up to a kilometre thick.

It's an astounding process to witness - a surreal combination of banging machinery and sci-fi precision.

If Tata's plans bear fruit, with a bit of modification this mill should be able to make thicker coils that could be used to help build the floating wind turbines off in the Celtic Sea.

If they invest in electric arc furnaces that steel could be made with only a fraction of the carbon emissions it produces today.

There is a tantalising prize.

The UK, which pioneered the use of coking coal to make iron in the 18th century and invented mass manufacture of steel in the 19th century, could become the first developed economy to have (nearly) completely decarbonised its steel sector.

Then again, it's just as possible that things go in a different direction.

The country that invented the large-scale steel industry could plausibly become the first developed economy to allow its steel industry to go extinct.